which of the following is a type of machine safeguarding osha 10

There seem to be as many hazards created by moving machine parts as there are types of machines. Type A and B Gates are both recognized methods for power press safeguarding.

Machine Guarding Checklist For Abrasive Wheel Equipment Grinders Occupational Safety And Health Administration

Must prevent workers from lubricating a machine without removing the safeguard.

. OSHA Safety and Health Information Bulletin SHIB January 25 2013. The A gate is used in both full and part revolution clutch presses while the B gate is for part revolution presses only. Carrying tools and materials is permitted.

Course topics include machinery processes mechanical motions points of operation control of hazardous energy. Ad Nationwide OSHA Training Provider. 2 Improper use of the top of step ladders.

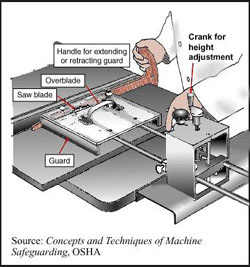

All machines consist of three fundamental areas the point of operation the power transmission device and the operating controls. The Occupational Safety and Health Administrations OSHAs requirements for machine guarding are found in 29 Code of Federal. Crushed hands and arms severed fingers blindness -- the list of possible machinery-related injuries is as long as it is horrifying.

2 Missing Machine Guard. Any machine part function or process that may cause injury must be. Interlock into the machines control system to stop operation when the sensing field photoelectric radio frequency or electromagnetic is disturbed.

The following references aid in recognizing hazards from ineffective machine guarding. Easily Meet OSHA Training Standards. 3 Lack of worker training.

Machine safeguarding helps protect workers from preventable injuries in all three areas. Machine guarding the statistics reflect top 10 violations showed 1910212 was No. Guidance is provided on the hazards associated with various types of machinery and the determination of proper machine safe guards.

A and B gate requirements. Safeguards are essential for protecting workers. This course covers the various types of common machinery machine safe guards and related OSHA regulations and procedures.

Guardrails have three main parts. Any part of a machine which ___ while in operation can cause a hazard. Top Safety Training Provider Since 1997.

Good machine safeguarding makes it very difficult for anyone to be exposed to the danger zone. Horizontal Injection Molding Machines - Interactive Safety Tour. The following are all machine safeguarding requirements except.

Replace it at the end of the shi L. A top rail a mid rail and a toe board. General Requirements 1910212 and Mechanical Power Transmission 1910219 were the No.

The ladder should be secured and extend 3 feet above the level you are accessing. Focuses on recognizing and controlling common amputation hazards associated with the operation and use of certain types of machines. Moving machine parts have the potential to cause severe workplace injuries such as crushed fingers or hands amputations burns or blindness.

8 during this period. The purpose of machine guarding is to protect the machine operator and other employees in the work area from hazards created during the. Movable guard - a guard connected by mechanical means eg hinges or slides to the machine frame or an adjacent fixed element.

Wrists are connected by cords and secured to a fixed anchor point which limit operators hands from reaching the point of operation at any time. Safeguards are essential for protecting workers from these preventable injuries. The ladder should be secured and extend 3.

1 Not having a portable ladder extend three feet above the landing. When you are protected by the with you opera ng the machine safeguards and others in the work 1. Any part of a machine which ___ while in operation can cause a hazard.

Interlocked guard - a guard attached and monitored by the control system in such a manner that it prevents the operation of hazardous machine functions under specified conditions. There seem to be as many hazards created by moving machine parts as there are types of machines. A Punching B Feeding and Ejection methods C Poinit of operation D In-going nip points.

Interlock guards make certain that the machine cannot be started until the guard screen is in the closed position and conversely the guard cannot be removed until the working parts have been stopped. 4 Occupational Safety and Health Administration List of Tables Table 1. Primary machine can fill in as.

Mechanical Engineering questions and answers. Commonly Used Machine Guards 12 Table 2. If a new guard causes interference 4.

Nip guard to in-running rolls and fixed railing or fencing to engines motors planning or shaping machine are of this type. Allows user to take a virtual. The following are all machine safeguarding requirements except.

An employee trained on his you can take it off as long as you area are protected also you are. _____ True or False. Must prevent workers from lubricating a machine without removing the safeguard.

There seem to be as many hazards created by moving machine parts as there are types of machines. Machine guarding and related machinery violations continuously rank among the top 20 of OSHA citations issued. Good to operate.

8 top OSHA violations for FY 2009 with 2045 and 1268 federal citations issued. Due to this fact OSHA Occupational Safety Health Administration has established a set of standards around machine guarding. The Basics of Machine Guarding Crushed hands and arms severed fingers blindness -- the list of possible machinery-related injuries is as long as it is horrifying.

Portable ladders may never be used. In fact Machine Guarding. The top 10 OSHNC serious violation for general industry standards cited in FY 2000 consisted of the following machine guarding related issues.

5 and 1910215 Abrasive Wheel Machinery was ranked No. Which of the following is a type of machine safeguarding. Types of Machine Guarding Restraint Devices.

A step ladder may be used if long enough. Types of Safeguarding Devices 13.

Etool Woodworking Table 1 Types Of Machine Guards Occupational Safety And Health Administration

Machine Guarding Training Osha Standards Vubiz

Safeguarding Equipment And Protecting Employees From Osha

Kpa Osha Machine Guard Requirement Compliance Checklist

Osha Standards For Industrial Companies Industrial Safety Health And Safety Poster Osha Safety Training

Osha General Industry Machinery And Machine Guarding 1910 Subpart O 1910 212 2017 01 04 Ishn